PISO-CAN200U-D

2-Port Isolated Protection Universal PCI CAN Communication Board with 9-pin D-sub connector

Features

The CAN (Controller Area Network) is a serial communication protocol, and efficiently supports distributed real-time control with a very high level of security. It is an especially suit for networking "intelligent" devices as well as sensors and actuators within a system or sub-system. In CAN networks, there is no addressing of subscribers or stations in the conventional sense, but instead prioritized messages are transmitted. As standalone CAN controller, PISO-CAN400/CAN200 can represent an economic solution of an active CAN board. It has two or four independent CAN bus communication ports with 5-pin screw terminal connector or 9-pin D-sub connector, and has the ability to cover a wide range of CAN applications. Besides, PISO-CAN400/CAN200 uses the new CAN controller Phillips SJA1000T and transceiver 82C250/251, which provides bus arbitration, error detection with auto correction and re-transmission function. It can be installed in a 5V PCI slot and supports true “Plug & Play”.

The CAN (Controller Area Network) is a serial communication protocol, and efficiently supports distributed real-time control with a very high level of security. It is an especially suit for networking "intelligent" devices as well as sensors and actuators within a system or sub-system. In CAN networks, there is no addressing of subscribers or stations in the conventional sense, but instead prioritized messages are transmitted. As standalone CAN controller, PISO-CAN400/CAN200 can represent an economic solution of an active CAN board. It has two or four independent CAN bus communication ports with 5-pin screw terminal connector or 9-pin D-sub connector, and has the ability to cover a wide range of CAN applications. Besides, PISO-CAN400/CAN200 uses the new CAN controller Phillips SJA1000T and transceiver 82C250/251, which provides bus arbitration, error detection with auto correction and re-transmission function. It can be installed in a 5V PCI slot and supports true “Plug & Play”.

Applications

- CAN bus communication application.

- DeviceNet, CANopen, CAN J1939, SDS(System Wide Network) protocol application.

- Control System

- Building Automation

- Factory Automation

- Distributed data acquisition.

Features

- Two independent CAN bus 2.0A/2.0B communication ports

- Compatible with CAN specification 2.0 parts A and B

- On-board optical isolation protection

- Programmable transfer rate up to 1 Mbps

- 2500 Vrms photo couple isolation on the CAN bus

- Jumper select 120Ω terminator resistor for each port

- Direct memory mapping to the CAN controllers

- 33MHz 32bit 5V PCI bus (V2.1) plug and play

[PISO-CAN200-D/T only]

- PCI card, supports 5V PCI bus

[PISO-CAN200U-D/T only]

- Universal PCI card, supports both 5V and 3.3V PCI bus

Note: We have verified to drive 100 CAN nodes at the same time via one CAN port of PISO-CAN200.

RTX Driver

In order to satisfy the users to apply the RTX system, ICPDAS provides the RTX driver for PISO-CAN series CAN card. If users want to combine the CAN communication interface in their time-critical system, the RTX driver of the PISO-CAN series CAN cards can help them to do this easily and quickly. Furthermore, the name and parameters of the APIs in the RTX driver are the same as in the Windows driver. Users don’t need to pay more efforts to study how to use the APIs of the RTX driver if they have used the Windows driver before. The RTX driver increases the additional worth of the PISO-CAN series CAN cards, and satisfies the users to get the highly real-time system. By owing to the feature of high price performance and highly real-time, PISO-CAN series CAN cards will be applied in more wide and more variant CAN applications.

Features:

- The name and parameters of the APIs in RTX driver are the same as them in the Windows driver. Users don’t need to learn the new usage if they have used the PISO-CAN series CAN card before

- If the PISO-CAN series CAN card can get the independent IRQ, it supports interrupt function

- Direct I/O control and highly real-time feature

- Support Windows2000 SP4, and Windows XP SP2 OS

- Support RTX version 8.0 or later

Real-time Test:

- Platform: Windows XP SP2+PEX-CAN200i

- Device: I-7186EXD-CAN with MiniOS7 (single tasking OS)

- Send and receive 10000 CAN 2.0B 8-byte messages. Repeat this procedure for 10 times

SocketCAN Driver

The SocketCAN is based on the Linux operating system, and it contains the implementation interface of the network stack and the hardware driver. The hardware manufacturers program the hardware driver for the SocketCAN, and the network stack provides the standard BSD Socket APIs for users. Therefore, from the users’ point of view, they can easily and quickly program their applications without being familiar with the various APIs of the different hardware interface through the SocketCAN network stack.

We have provided the SocketCAN drivers for several kinds of CAN interface cards. Users can implement their SocketCAN-based application on the Linux platform by using these cards. Besides, we also support static library of CANopen/DeviceNet master on x86 hardware platform. It can help users communicate with CANopen/DeviceNet slaves more easily.

Features:

- Support Linux kernel version 2.6.31~2.6.34 (x86 hardware platform only)

- Provide CANopen/DeviceNet master static library

- Standard interface for SocketCAN package. Users can use extended BSD socket APIs, you can program the CAN application as building a socket program

- Support Virtual CAN interface. Users can map several virtual CAN port into one physical CAN port. Each virtual CAN port has its own socket. Through these sockets, users can build the multi-thread application more easily

- Provide the RAW socket, CANopen master and DeviceNet master demos

- Good price-performance for economical applications

Note:

Hardware platform:Intel(R) Core(TM)2 CPU 6320 @ 1.86GHz, DDR2 667MHz 1.5GB

Software platform:Kernel-2.6.32, Distro- Debian GNU/Linux 5.0

Utility

- Can be a CAN system monitor tool with CAN cards

- It is a good tool to test CAN system

- Send/Receive/Record CAN messages

- Provide cyclic transmission function

- Record the CAN messages with filtered ID and time stamp

- Support: Win98/Me/2000/XP-32bit/7-32bit/7-64bit (not for Win 7 Ultimate-64bit)

ActiveX Tool

In order to use PISO-CAN200/400 easier, we provide a PISOCANX ActiveX component (OCX).

It is a useful element to develop the PISO-CAN200/400 application on different program development platform, and it also help users to reduce their development period.

Specially, users can use this in their SCADA softwares which support ActiveX technology. It would be possible to use SCADA software to control or monitor CAN devices. If users want to get PISOCANX, it will be found after installing the PISO-CAN200/400 driver with 1.16 version or later.

LabVIEW Tool

In order to apply the PISO-CAN200/400 to CAN network with NI LabVIEW, we provides a LabVIEW 7/7.1 toolkit for the purpose. It is a useful tool to develop the CAN-relative application in NI LabVIEW environment by using PISO-CAN200/400. It is easy to use and can help user to rapidly reduce their program development cycle. If users want to develop a LabVIEW industrial application with CAN network, the LabVIEW CAN driver is very helpful.

CAN LabVIEW Tool Features:

- Support extension arbitration id

- Support debug receive mode

- Start byte of output

- Support LabVIEW 7/7.1

- Scaling range to select

- Two languages, German and English

- Selectable data rates (baud): 10K, 20K, 50K, 125K, 250K, 500K, 800K, 1M, and user defined

DASYLab Tool

In order to easy to use the PISO-CAN200/400 to CAN network for user. We provides a DASYLab version 8.0 toolkit for the purpose. It is a useful tool to develop the CAN-relative application in DASYLab environment by using PISO-CAN200/400. It can help user to rapidly reduce their program development cycle. If users want to develop a DASYLab industrial application with CAN network, the DASYLab CAN driver is very helpful.

CAN DASYLab Tool Features:

- Support extension arbitration id

- Support maximum 64 CAN ports

- Start byte of output

- Scaling range to select

- Sample rate from 50 ~ 5000 Hz

- Two languages, German and English

- Selectable data rates (baud): 10K, 20K, 50K, 125K, 250K, 500K, 800K, 1M, and user defined.

Virtual CAN

There are various communication interfaces among the CAN devices like PCI CAN board, Ethernet series and RS-232 series CAN module. According to different purpose of users’ projects, the users maybe need to choice different CAN products. Because of this situation, the programmer should develop different communication program to handle different CAN device. For example, the user should develop “Socket Client” to communicate with I-7540. When using I-7530, the users need “UART” technique to communicate with it. Nowadays, ICP DAS develop the Virtual CAN technique. The Virtual CAN driver is the excellent tool for users. It transforms whole CAN devices into Virtual CAN port. And then it generates Virtual CAN port like “VxCAN 1” or “VxCAN 2”. The users could send and receive CAN message by appointing the Virtual CAN port number. The users don't need to care about what kind of CAN device which is used.

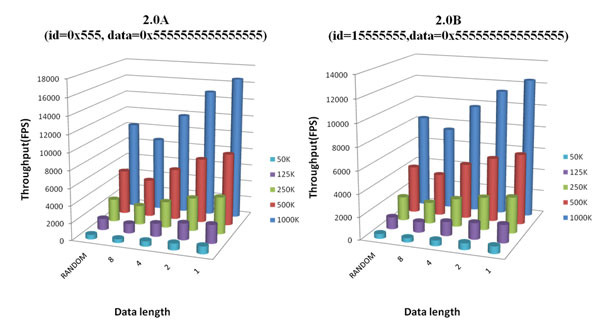

Performance Test

Test development:

OS:Windows XP SP 3

CPU:Intel Core 2 Duo 2.00 GHz

RAM:512 MB

Baud Rate(bps) |

CAN 2.0 A |

CAN 2.0 B |

Frame per sec. |

Frame per sec. |

|

1000 k |

7493 |

6387 |

800 k |

6185 |

5249 |

500 k |

4088 |

3463 |

250 k |

2134 |

1808 |

125 k |

1096 |

924 |

50 k |

438 |

370 |

20 k |

175 |

148 |

10 k |

88 |

74 |

Note:The test result is the average value of receiving 100000 CAN messages.

Specifications

Bus Interface |

|

Type |

Universal PCI, 3.3 V and 5 V, 33 MHz, 32-bit, plug and play |

CAN Interface |

|

Controller |

NXP SJA1000T with 16 MHz clock |

Transceiver |

NXP 82C250 |

Channel number |

2 |

Connector |

9-pin male D-Sub |

Baud Rate (bps) |

10 k, 20 k, 50 k, 125 k, 250 k, 500 k, 800 k, 1 M (allow user-defined baud rate) |

Terminator Resistor |

Jumper for 120 Ω terminator resistor |

Power |

|

Power Consumption |

250 mA @ 5 V |

Software |

|

Driver |

Windows 98/ME/NT/2K/XP/7, Linux 2.6.37, LabView, DASYLab |

Library |

VB 6.0, VC++ 6.0, BCB 6.0, Delphi 4.0 |

Mechanism |

|

Dimensions |

126mm x 22mm x 85mm (W x L x H) |

Environment |

|

Operating Temp. |

0 ~ 60 ℃ |

Storage Temp. |

-20 ~ 70 ℃ |

Humidity |

5 ~ 85% RH, non-condensing |