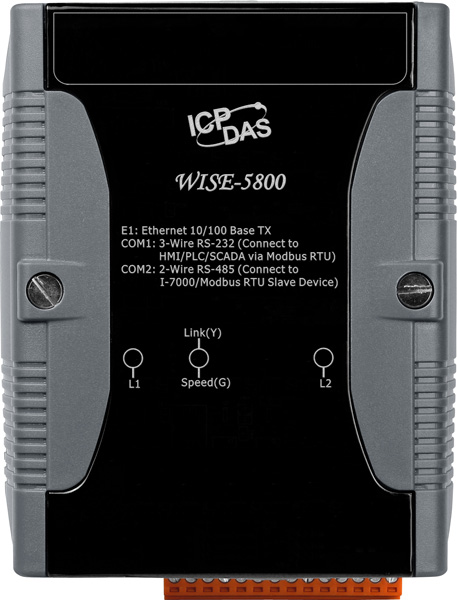

WISE-5800-MTCP

User-defined I/O & Data Logger Module for Modbus TCP Devices, communicates over ethernet, RS-232 and RS-485, supports operating temperatures from -25 ~ +75°C

Features

WISE (Web Inside, Smart Engine) is a product series developed by ICP DAS that functions as control units for use in remote logic control and monitoring in various industrial applications. WISE offers a user-friendly and intuitive web site interface that allows users to implement IF-THEN-ELSE control logic on controllers just a few clicks away; no programming is required. With its powerful and easy-to-use features, it will minimize the learning curve, shorten time to market and dramatically reduce the labor and cost spent on system development.

WISE-5800-MTCP supports an I/O expansion bus to implement various I/O functions such as D/I, D/O, A/D and D/A according to the XW-Board. In addition, WISE-5800-MTCP also supports Modbus TCP slave devices. Based on the connection ability with Modbus TCP slave devices, WISE-5800-MTCP can provide user more flexibility in application field.

WISE-5800-MTCP supports Modbus TCP/RTU protocol to make seamless integration with SCADA software available. It includes all advantages which WISE series controllers can provide. In addition, WISE-5800-MTCP provides data logger function with microSD card, it can record I/O channel value by event trigger or regular time period. The data files can be sent back by Email or FTP. All setting can be completed through browser.

- Built-in Web Server for IF-THEN-ELSE rule setting

- Built-in IF-THEN-ELSE rule engine for logic operation

- No more programming. Click and get done!

- Support I/O, Counter, Timer, Email, Recipe operations

- Data logger and data files send back function supported

- Modbus TCP/RTU Protocol for SCADA Software Seamless Integration

- Support XW-Board

- Support Modbus TCP Slave Devices(Up to 7)

- SNTP Time Synchronization Supported

Applications

Building Automation, Factory Automation, Machine Automation, Remote Maintenance, Remote Diagnosis, Testing Equipment, etc.

Specifications

Support I/O Module List

| I/O Type | Functions | Modules | |

| XW-Board | DI/DO | XW107, XW110 | |

| DI/DO/AI/AO | XW304, XW310, XW310C | ||

| Modbus TCP Slave Module | Coil Output / Discrete Input / Input Register / Holding Register | ||

Hardware Specifications

| CPU Module | |

| CPU | 16-bit CPU |

| SRAM | 768 KB |

| Flash | 512 KB |

| EEPROM | 16 KB |

| NVRAM | 31 Bytes |

| microSD Expansion | Support 1/2/4 GB microSD |

| RTC (Real Time Clock) | Provide second, minute, hour, date of week, month and year |

| Watchdog | Yes |

| Communication Ports | |

| Ethernet | RJ-45 x 1, 10/100 Base-TX (Auto-negotiating, Auto MDI/MDI-X) |

| COM 1 | RS-232 (TxD, RxD, RTS, CTS, GND), non-isolated, Speed: 115200 bps max. |

| COM 2 | RS-485 (D2+, D2-), self-tuner ASIC inside, non-isolated, Speed: 115200 bps max. (Reserved) |

| LED Indicators | |

| System LED | Yes (Red) |

| Ethernet Link LED | Yes (Green : Ethernet link detected, Flashing Green : Ethernet packet received) |

| Hardware Expansion | |

| I/O Expansion Bus | Yes |

| Power Requirements | |

| Protection | Power Reverse Polarity Protection |

| Frame Ground | Yes (for ESD Protection) |

| Input Range | 12 ~ 48 VDC |

| Redundant Power Input | Yes |

| Power Consumption | 2.0 W |

| Mechanical | |

| Dimensions (W x H x D) | 91 mm x 123 mm x 52 mm |

| Installation | DIN-Rail |

| Environment | |

| Operating Temperature | -25 ~ +75 °C |

| Storage Temperature | -30 ~ +80 °C |

| Ambient Relative Humidity | 10 ~ 90% RH (non-condensing) |

Software Specifications

| Functions | |

| Rule Configuration Website | Access Web server on WISE controllers to edit and upload logic rules through web browser. |

| 36 IF-THEN-ELSE Logic Rules | 3 IF conditions with AND or OR operators 3 THEN actions and 3 ELSE actions |

| 48 Internal Registers | Hold temporary variables and read/write data via Modbus/TCP address. |

| 12 Timers | Delay / Timing functions. |

| 12 Schedules | Setup prescheduled routine tasks. |

| 12 Emails | Send Email messages to pre-set Email receivers. |

| 12 CGI Commands | Send pre-set CGI commands. |

| 12 Recipes | Set up THEN/ELSE action groups. |

| Data Logger | Set up the Data Logger configuration, include the data record format, and data file sending operation. |

| Modbus TCP/RTU Protocol | Real time control and monitoring I/O channels and system status of controllers via SCADA software. |

| IF Conditions | |

| DI Channel | ON、OFF、ON to OFF、OFF to ON、Change |

| AI Channel | =、>、<、>=、<=(value) |

| Internal Register | |

| DI Counter | =、>、<、>=、<=(value)、Change |

| Timer | Timeout、Not Timeout |

| Schedule | In Range、Out of Range |

| Rule Status | Enable、Disable |

| THEN / ELSE Actions | |

| DO Channel | ON、OFF、Pulse Output ( apply to XW-Board only) |

| AO Channel | Change the value |

| Internal Register | |

| DI Counter | Reset |

| Timer | Start、Reset |

| Schedule | Enable、Disable |

| Send | |

| CGI Commands | |

| Recipe | Execute |

| Data Logger | Start、Stop、One-Time Log |

| Rule Status | Enable、Disable |